2026 Top Iron Castor Wheels Features and Benefits Guide?

Iron Castor Wheels have become essential components in industries that require reliable mobility solutions. According to recent industry reports, the global market for caster wheels is projected to grow at a CAGR of 5.2% from 2022 to 2026. This growth is attributed to the increasing demand for durable, heavy-duty tools in manufacturing and logistics sectors.

Iron Castor Wheels offer unique features that enhance performance. Their robust construction enables them to bear heavy loads with ease, with some models capable of supporting up to 2,000 pounds. This is particularly relevant in warehouses and factories where durability is needed. However, choosing the right wheel can be challenging. Factors such as load capacity, wheel size, and environmental conditions must be taken into account.

While Iron Castor Wheels provide numerous advantages, they are not without drawbacks. Users must consider potential issues, such as noise levels and floor surface impacts. Over time, the suitability of a wheel may diminish, prompting reevaluation. Identifying the best features and benefits for specific applications is crucial for optimal performance.

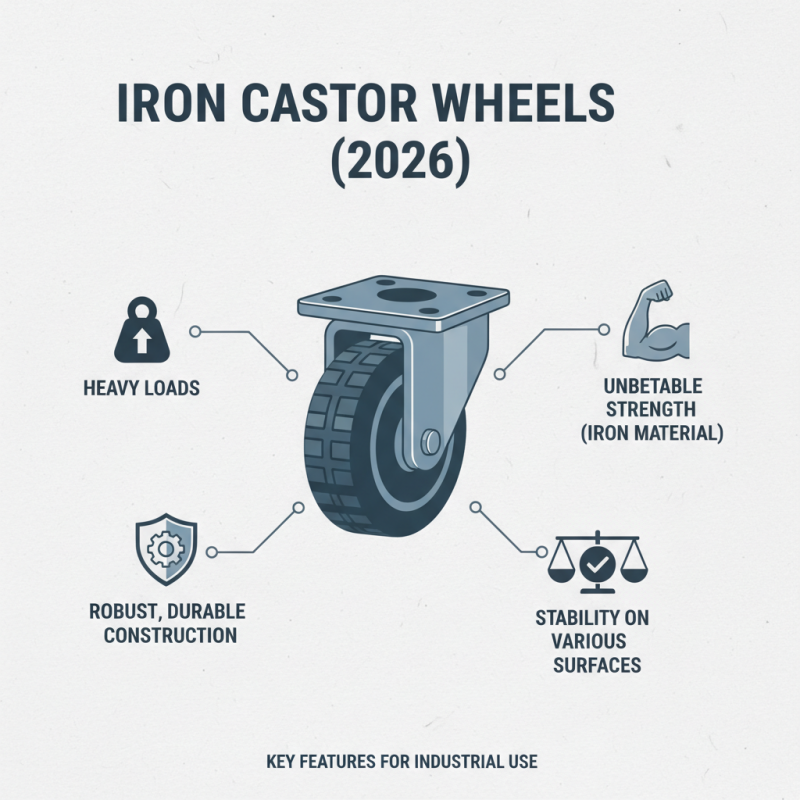

2026 Iron Castor Wheels: An Overview of Features and Specifications

When considering iron castor wheels in 2026, it’s essential to look at their features. These wheels are designed for heavy loads. They come with a robust, durable construction. The iron material offers strength that is hard to beat. Many users appreciate the stability these wheels provide on various surfaces.

Specifications vary, but weight capacity is a big factor. Most iron castor wheels can support substantial weight. This makes them ideal for industrial and commercial applications. The swivel and rigid options cater to different needs. Some configurations allow for enhanced maneuverability. People also love the heat resistance, making them suitable for extreme environments.

However, the surface finish may require attention. While they are tough, imperfections in the coating can lead to rust. Regular maintenance becomes crucial. Users sometimes overlook this, leading to premature wear. Engaging in routine checks can prolong the life of these wheels. Considerations of noise level during operation are also vital. Some may find them louder than expected. Thus, evaluating the environment where they will be used is important.

Key Benefits of Using Iron Castor Wheels in Industrial Applications

Iron castor wheels offer notable advantages in various industrial applications. They are renowned for their strength and durability. Industries often require robust solutions for transporting heavy loads. Iron wheels excel in handling challenging environments. They withstand high temperatures and resist wear effectively. This makes them suitable for foundries and warehouses.

The weight of iron castor wheels provides stability during movement. They perform well on uneven surfaces, reducing the risk of tipping. However, their heaviness can be a drawback. Moving equipment with heavy wheels can be cumbersome. Frequent adjustments may be needed, which can slow down processes.

Moreover, these wheels produce more noise than other materials. This characteristic might not be ideal for all settings. Nonetheless, they excel in environments where noise is less of a concern. Users should assess their specific needs when choosing wheels. Evaluating both benefits and drawbacks ensures a better fit for industrial requirements.

Comparative Analysis: Iron Castor Wheels vs. Other Wheel Materials

Iron castor wheels stand out when compared to wheels made from other materials. The durability and strength of iron are significant advantages. Unlike plastic or rubber wheels, iron castor wheels can bear heavier loads. They perform well on uneven surfaces. Their stability is often unmatched, especially in industrial settings. However, they can be prone to corrosion without proper maintenance.

While many opt for lighter materials for easier handling, iron offers unique resilience. Rubber wheels may provide smoother rides, but they wear out faster under heavy use. Iron wheels can be noisy but excel in environments that require robust performance. The weight may hinder mobility, yet it provides unwavering support. Users should weigh these traits against their specific needs.

One downside of iron castor wheels is their tendency to mark floors. This can be an issue in decorative spaces. Additionally, they may require more effort to move. Users should reflect on these aspects before making a decision. Balancing durability with usability is key when choosing the right wheels for various applications.

Load Capacity and Durability: Understanding Iron Castor Wheels Performance

Iron castor wheels are often chosen for their exceptional load capacity and durability. These wheels can handle heavy weights, making them ideal for industrial settings. They are often made of strong materials that resist wear and tear. Over time, some users notice that while they are durable, they can become noisy. This can be an issue in quiet environments.

The performance of iron castor wheels is influenced by their design. A wider wheel can distribute weight more evenly. This helps to prevent damage to flooring. However, these wheels can leave marks on certain surfaces. It’s essential to consider the type of surface before making a decision. Misjudging this aspect can lead to regrets later.

In extreme conditions, even the toughest iron wheels might struggle. High temperatures can affect their performance. The weight they bear must be monitored closely. Some users have experienced problems when exceeding recommended limits. Balancing load capacity with the right application is crucial for optimal function. Often, users are left wishing they had assessed their needs more thoroughly before purchase.

2026 Top Iron Castor Wheels Load Capacity and Durability

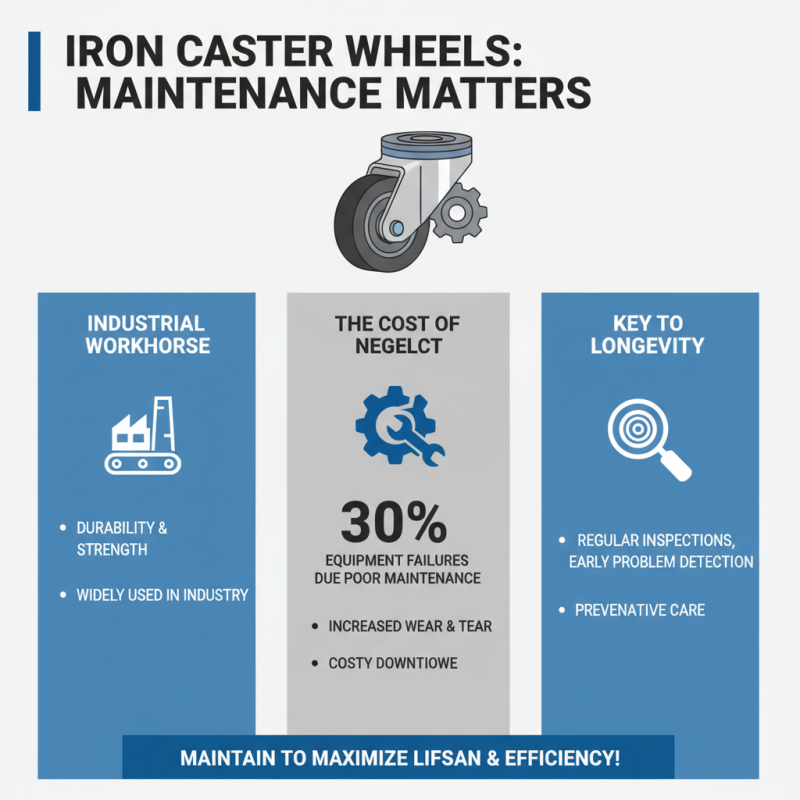

Maintenance and Safety Considerations for Iron Castor Wheels in Use

Iron castor wheels are widely used in industrial settings for their durability and strength. However, proper maintenance is crucial for their longevity. Neglecting maintenance can lead to increased wear and tear. According to a recent industry report, about 30% of equipment failures are linked to poor maintenance practices. Regular inspections can identify problems early, helping to avoid costly downtimes.

Safety considerations play a vital role too. Users must ensure that the wheels are rated for the load they carry. Overloading can lead to wheel failure, which may cause accidents. Studies show that improperly maintained castor wheels contribute to 15% of workplace accidents. Simple actions, like checking for debris and cleaning the wheels regularly, can significantly enhance safety. It's surprising how often these small tasks are overlooked.

Moreover, it's essential to choose the right environment for iron castor wheels. Exposure to harsh chemicals can lead to rust and degradation. Many facilities underestimate the impact of environmental factors on castor longevity. Adjusting the workspace with proper flooring can also help. A smooth surface reduces friction, thus prolonging the life of the wheels. Investing time in maintenance and safety can yield significant benefits in an organization's operational efficiency.

Related Posts

-

How to Choose the Right Iron Castor Wheels for Your Project

-

The Top 5 Benefits of Using Cast Iron Casters for Your Heavy-Duty Equipment

-

Top 10 Cast Iron Casters to Watch in 2025 for Ultimate Durability

-

Understanding the Benefits and Applications of Iron Castor Wheels in Everyday Life

-

Maximizing Efficiency with the Best Caster Trolley in Your Operations

-

Why Choose Iron Castor Wheels for Your Heavy Duty Equipment Needs