2026 Top Caster Trolley Wheels Which One Should You Choose?

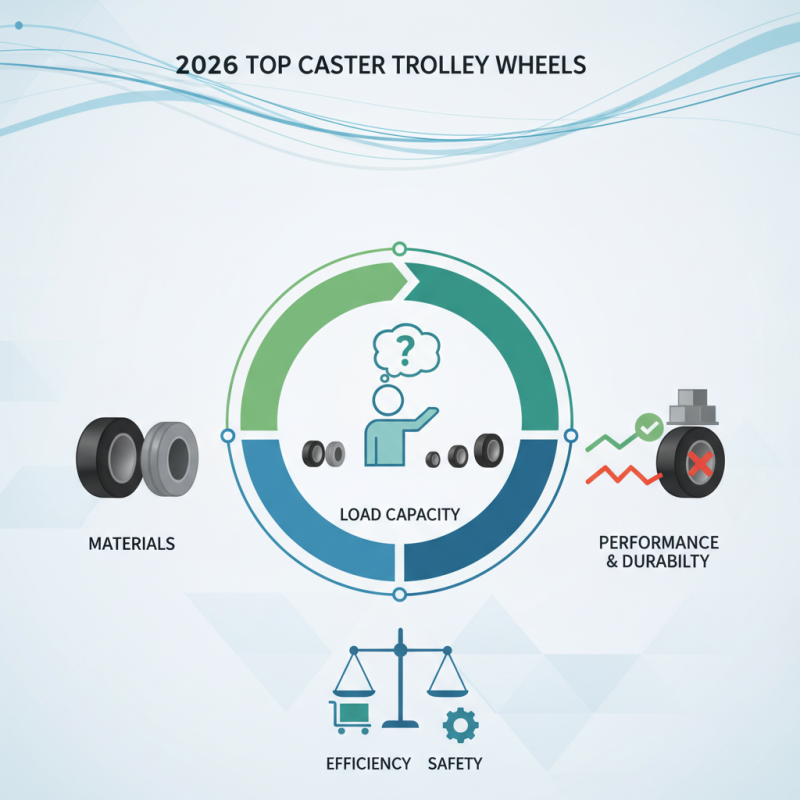

When considering the best Caster Trolley Wheels for your needs, expert John Smith emphasizes, "Choosing the right wheels can make all the difference in efficiency." In 2026, the market is flooded with options, leaving consumers overwhelmed. Identifying the ideal wheels requires understanding various factors.

Caster Trolley Wheels come in different materials, sizes, and load capacities. Each choice affects performance and durability. For instance, rubber wheels are quiet and smooth, while hard plastic wheels might suit heavier loads. Each option presents its own set of pros and cons.

However, buyers often overlook specifics. Some might choose wheels solely based on aesthetics, ignoring load ratings. Honest reflection on your needs is crucial. Don’t just follow trends; analyze what works best for your situation. Making the right choice in Caster Trolley Wheels impacts both productivity and safety.

The Importance of Wheel Material in Caster Trolley Performance

When choosing caster trolley wheels, the material significantly affects performance. Different materials offer varying benefits and drawbacks. For instance, rubber wheels provide excellent traction and shock absorption. They are ideal for uneven surfaces. However, they may wear out faster than harder materials.

Polyurethane wheels are a great alternative. They combine the best of both worlds. They are durable and resistant to chemicals. Data shows that polyurethane wheels can last 50% longer than standard rubber options. This makes them suitable for industrial applications where longevity is essential. On the other hand, metal wheels have high load capacities but can damage floors.

Choosing the right material shouldn't be solely based on initial cost. Long-term performance is crucial. A cheaper plastic option may save money upfront, but it could lead to frequent replacements. This ultimately increases costs. Therefore, evaluating material properties against your specific needs is vital.

Load Capacity Ratings: Selecting the Right Wheels for Heavy Loads

When selecting caster trolley wheels, load capacity ratings play a key role. Heavy loads require wheels designed for strength and durability. It can be tempting to choose a wheel based solely on size or appearance, but that's a mistake. Each wheel must match the specific weight it will carry.

Consider the material of the wheel too. Hard materials, like polypropylene, can handle heavier loads but may not perform well on uneven surfaces. Softer materials, such as rubber, offer better shock absorption. Remember, the wheel's environment matters. Dust and debris may create friction and slow down your trolley.

Choosing the right wheels is a balance. You need to think critically about the weight, surface type, and wheel material. It's easy to overlook these details under pressure. Yet, missing the right match can lead to significant issues down the line. Tracking load limits and assessing your needs is vital for safe movement.

Comparative Analysis of Wheel Sizes for Optimal Maneuverability

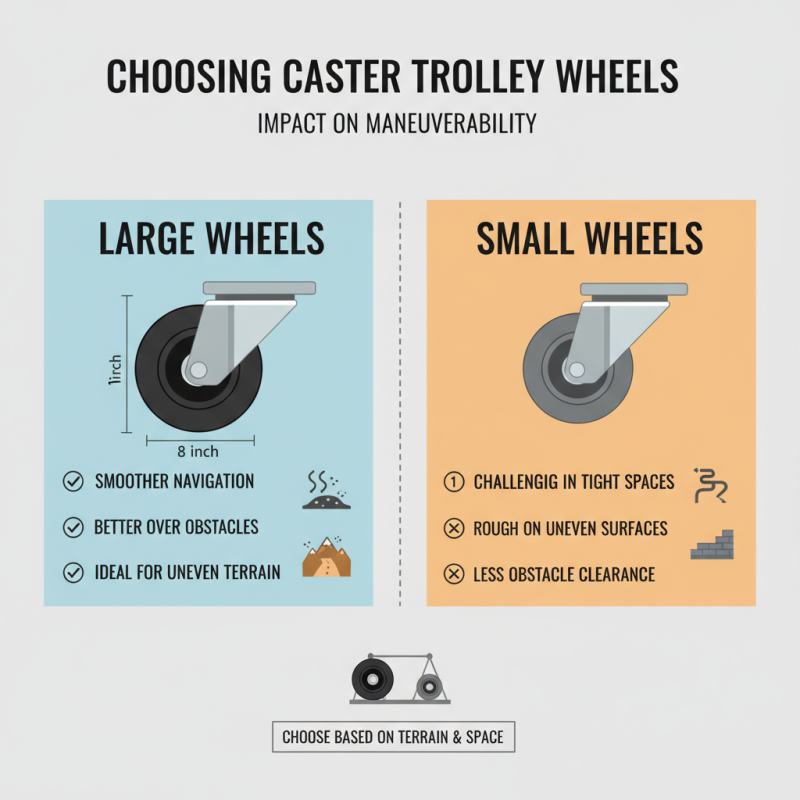

Choosing the right size of caster trolley wheels can significantly impact maneuverability. Larger wheels offer smoother navigation over rough surfaces. They can handle obstacles better, making them ideal for uneven terrains. However, large wheels can be more challenging to control in tight spaces.

Smaller wheels excel in compact environments. They provide agility and precision. If your cart often navigates narrow hallways, smaller wheels may be the better choice. But keep in mind, they may struggle on rough surfaces. A balance must be struck based on your needs.

**Tips:** Always test the wheels on your intended surface. It helps avoid surprises later. If unsure, consult with experts or user experiences. A wheel's material can affect performance too. Don’t overlook this aspect when making your decision.

Understanding Wheel Bearing Types and Their Impact on Functionality

When choosing caster trolley wheels, understanding wheel bearing types is essential. Different bearings affect how smoothly and efficiently wheels perform. Generally, there are two main types: ball bearings and roller bearings. Ball bearings are versatile and commonly used in various applications. They provide decent load capacity and speed but may not be suitable for heavy-duty tasks.

However, roller bearings offer increased loads and durability. A report by the Industrial Research Institute indicates that roller bearings can handle up to 25% more weight than equivalent ball bearings. This is crucial for heavy trolleys in industrial settings. The choice of bearing type can significantly influence operational efficiency and longevity.

Additionally, wheel materials can alter performance. For instance, polyurethane wheels are known for better shock absorption and floor protection. Yet, they may wear out faster under constant stress. A study from the Global Wheels Association highlighted that improper wheel selection can lower mobility by 30%. Selecting the right wheel bearing is often overlooked but can drastically impact usage. Each component matters in ensuring optimal functionality.

2026 Top Caster Trolley Wheels - Understanding Wheel Bearing Types

Trends in Caster Wheel Design: Innovations for 2026 and Beyond

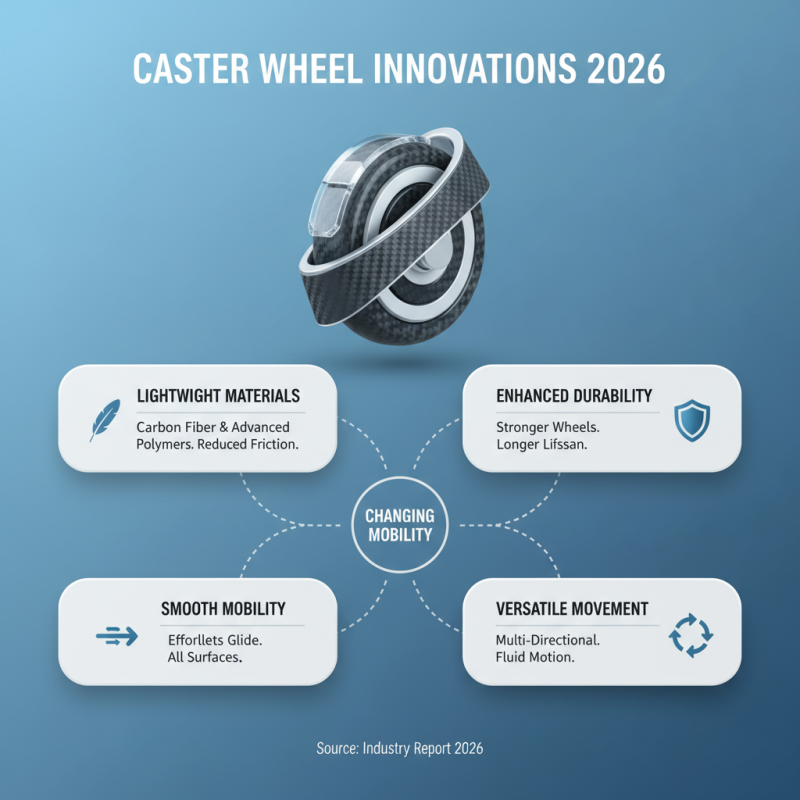

Innovations in caster wheel design are changing the way we think about mobility. In 2026, lightweight materials like carbon fiber and advanced polymers are becoming popular. These materials reduce friction. They enhance durability, making wheels easier to move. Users appreciate the smooth glide they provide on various surfaces. Wheels are also becoming more versatile. Some now feature multi-directional capabilities, allowing for more fluid movement.

Trends also include smart technology integration. Sensors can now monitor weight and surface conditions. This feedback helps users make informed decisions. However, not all designs succeed. Some concepts feel over-engineered, complicating simple tasks. Others may neglect basic functionalities in favor of aesthetics. Selecting the right caster wheel can feel overwhelming. Prioritizing practical features over flashy designs is wise. Experimenting with different styles may lead to better performance in real-world applications.

Related Posts

-

Global Leader in Caster Connection Wheels Manufacturing for Export Quality and Innovation

-

Exploring the Versatility of Swivel Plate Casters: Ultimate Guide to Choosing the Right Caster for Your Needs

-

How to Choose the Best Furniture Castor Wheels for Your Home or Office

-

Top 10 Furniture Castor Wheels for Smooth Mobility and Easy Movement

-

Top Swivel Plate Casters: Choosing the Best for Your Project Needs

-

What is a Caster Swivel Wheel and How to Choose the Best One for Your Needs