What is a Caster Swivel Wheel and How to Choose the Best One for Your Needs

In the world of mobility solutions, the Caster Swivel Wheel stands out as an essential component, providing flexibility and ease of movement across a variety of applications. According to industry expert John Peterson, a leading engineer in caster technology, “Choosing the right Caster Swivel Wheel can dramatically enhance workplace efficiency and reduce strain.” This statement highlights the importance of selecting the appropriate swivel wheels tailored to specific needs.

A Caster Swivel Wheel not only needs to provide smooth maneuverability but should also be compatible with the environment it’s intended for, whether it’s for industrial carts, office furniture, or even heavy-duty equipment. As the market offers a growing range of options, understanding the factors that influence the selection of a Caster Swivel Wheel is paramount for both professionals and everyday users. By delving into the various types and features available, users can make informed choices that ensure durability, functionality, and optimal performance in their respective settings.

What is a Caster Swivel Wheel?

A caster swivel wheel is a type of wheel designed to provide enhanced mobility and maneuverability for various objects and equipment, such as trolleys, furniture, and robots. These wheels typically have a mounting stem that allows for rotation in any direction, enabling smooth and effortless movement. They are used in numerous applications, from industrial machinery to luggage, enhancing functionality and convenience. Recent innovations show that caster wheels can also be engineered to meet specific challenges, like overcoming high steps in mobile robots, thereby greatly enhancing their performance.

When selecting the best caster swivel wheel for your needs, consider factors such as size, material, and load capacity. Different materials, like polyurethane and rubber, offer varying degrees of durability and noise reduction while rolling. Additionally, the wheel size should match the intended application; larger wheels can handle rough terrains, while smaller ones are ideal for more controlled environments. The growing market for heavy-duty and motorized caster wheels highlights the increasing demand for robust solutions in construction and manufacturing, making it essential to choose wheels that align with your specific requirements.

Types of Caster Swivel Wheels and Their Applications

Caster swivel wheels are versatile components used in various applications, and understanding their types can significantly impact efficiency and functionality. The primary types of caster swivel wheels include rubber, polyurethane, and metal.

Rubber wheels are known for their excellent shock absorption and quiet operation, making them ideal for use on hard floors in settings like hospitals and offices. Polyurethane wheels, on the other hand, offer a balance between durability and ease of movement, making them suitable for both indoor and outdoor applications. They resist wear and tear while providing smooth rolling, making them perfect for carts used in warehouses.

Metal casters, typically made from steel, are designed for heavy-duty applications. They are ideal for industries that require rugged and durable solutions, such as manufacturing and construction. These wheels can support significant weights and withstand rough surfaces, making them a reliable choice for heavy equipment and industrial machinery.

When choosing the right caster swivel wheel, it is crucial to consider the specific application, weight capacity, and the surface it will be used on to ensure optimal performance and longevity.

Key Factors to Consider When Choosing a Caster Swivel Wheel

When selecting the right caster swivel wheel for your requirements, several key factors come into play that can significantly impact performance. First, consider the load capacity. According to a report by the Caster and Wheel Manufacturers Association, choosing a wheel that can support at least 25% more than your expected load is advisable to prevent wear and tear. Secondly, the material of the wheel is crucial. For instance, polyurethane wheels are known for their durability and smooth movement on various surfaces, making them ideal for industrial settings where heavy loads are common.

Tip: Always evaluate the floor surface where the swivel wheel will be used. Hard surfaces benefit from hard wheels that minimize debris collection, while soft wheels work best on uneven surfaces to absorb shock.

Another significant factor is swivel capability. Caster wheels with a wider swivel radius provide better maneuverability in tight spaces. Industry studies suggest that wheels equipped with precision ball bearings improve rotation and reduce friction, leading to less strain on the user and equipment.

Tip: Verify the maintenance requirements of your selected caster to ensure longevity and optimal performance; regular inspections can prevent unexpected breakdowns.

What is a Caster Swivel Wheel and How to Choose the Best One for Your Needs - Key Factors to Consider When Choosing a Caster Swivel Wheel

| Caster Wheel Type | Load Capacity | Material | Wheel Diameter | Locking Mechanism | Swivel Radius | Ideal Surface Type |

|---|---|---|---|---|---|---|

| Standard Caster | 200 lbs | Polyurethane | 4 inches | Total Lock | 5 inches | Hard Floors |

| Heavy-Duty Caster | 600 lbs | Rubber | 6 inches | Directional Lock | 6 inches | Concrete |

| Industrial Caster | 800 lbs | Steel | 8 inches | None | 8 inches | Rugged Terrain |

| Furniture Caster | 100 lbs | Nylon | 2 inches | Brake | 3 inches | Wood Floors |

How to Measure the Load Capacity for Caster Swivel Wheels

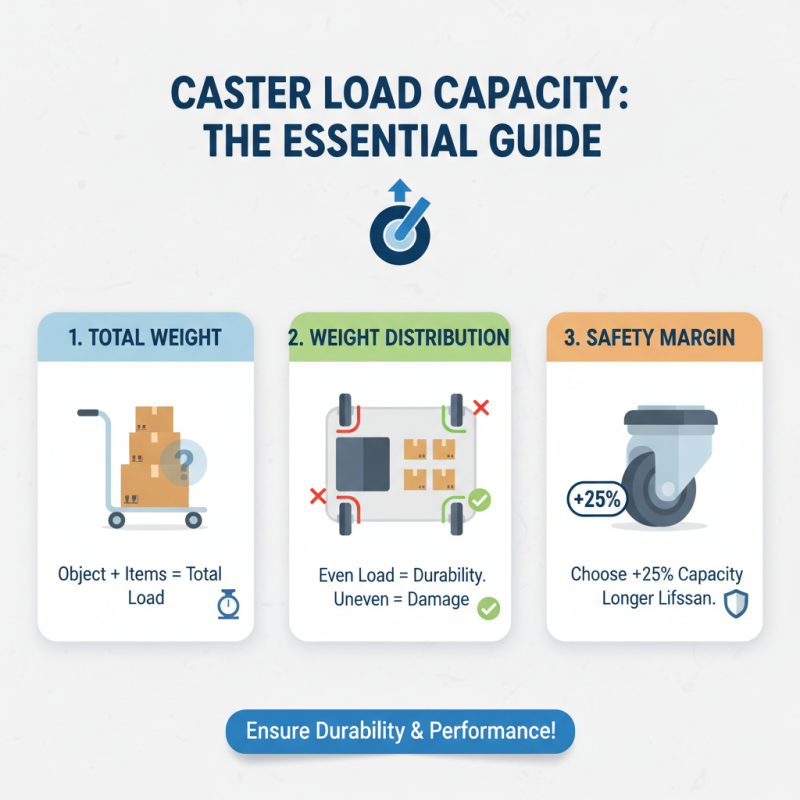

When selecting the right caster swivel wheel for your needs, understanding the load capacity is critical. Load capacity refers to the maximum weight a caster can support safely. To measure it, start by determining the total weight of the object you plan to move, including any additional items that may be added later. Factor in the weight distribution, as uneven loads can lead to wear and damage over time. It is generally advisable to choose casters with a higher load capacity than the calculated weight to ensure durability and performance.

Tips: Always check the manufacturer's specifications for each caster, as load capacities can vary significantly depending on materials and design. Consider the surface on which the caster will be used; different surfaces can affect the performance and longevity of the wheels.

Another critical aspect to consider is the type of bearing used in the swivel. High-quality bearings can greatly enhance the smoothness of movement and reduce the effort required to maneuver the object. When in doubt, consult with a specialist to choose the best caster swivel wheels tailored to your specific workload and environment.

Maintenance Tips for Caster Swivel Wheels to Ensure Longevity

Maintaining caster swivel wheels is essential to ensure their longevity and optimal performance. Regular inspections are the first step in upkeep; you should check for signs of wear, such as cracks or deformities in the wheel or frame. Ensuring that the wheel is free from debris or obstructions can prevent potential damage. Additionally, pay attention to the wheel's rotation; it should turn smoothly without any hitches. If you notice resistance, it may be time to clean or lubricate the swivel mechanism.

Lubrication plays a crucial role in extending the lifespan of your caster wheels. Using appropriate lubricants, such as silicone spray or grease, can help reduce friction and prevent rust formation. Applying lubricant to the swivel and axle points can enhance mobility and decrease wear. Furthermore, considering the environment where the wheels will be used is important. Selecting wheels made from materials suited for specific surfaces or conditions, such as anti-static or weather-resistant options, will ultimately contribute to their endurance and usability. Regular maintenance not only conserves your investment but also ensures the smooth operation of your equipment.

Related Posts

-

Global Leader in Caster Connection Wheels Manufacturing for Export Quality and Innovation

-

Ultimate Guide to Choosing the Right Caster Connection Wheels for Your Needs

-

Understanding the Challenges of Heavy Caster Wheels in Industrial Applications

-

What Are the Key Features of Caster Trolley Wheels

-

How to Choose the Right Caster Trolley Wheels for Your Needs

-

Exploring the Versatile Applications of Best Furniture Castors in Modern Workspace Design