How to Choose Heavy Castor Wheels for Your Industrial Needs?

In the world of industrial equipment, selecting the right Heavy Castor Wheels is crucial. These wheels bear significant loads and impact productivity. As industry expert John Smith states, "Choosing the right wheels can make or break your operations."

Heavy Castor Wheels come in various sizes and materials, each suited for specific applications. For example, steel wheels perform well in tough conditions, while rubber wheels are quieter and protect flooring. Knowing the environment and load requirements is essential.

Every choice has its trade-offs. High-capacity wheels might be overkill for lighter tasks. Conversely, using improper wheels can lead to inefficiencies and accidents. Therefore, careful consideration is essential. Investing time in understanding Heavy Castor Wheels pays off in the long run.

Factors to Consider When Selecting Heavy Castor Wheels for Industry

When selecting heavy castor wheels for industrial use, several key factors must be considered. Load capacity is critical. Each wheel must support the weight of machinery or materials. If the wheels fail, the results could be costly. You'll want to check the specifications to ensure they meet your needs.

Material is also significant. Different environments require different types of wheels. For instance, rubber wheels provide good shock absorption. However, they may wear out quickly in harsh conditions. On the other hand, metal wheels are durable but can damage floors. It’s essential to balance durability with the surface you will be working on.

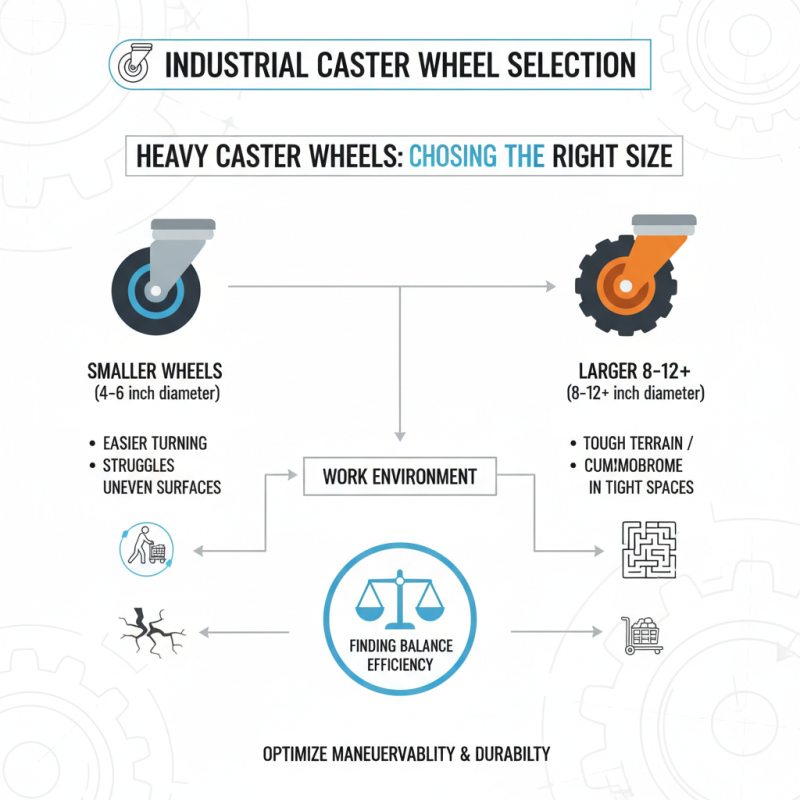

Furthermore, wheel size affects performance. Larger wheels roll over obstacles more easily, providing a smoother ride. But, they may not fit all equipment. Visibility and maneuverability also matter. Sometimes, a smaller wheel may allow for better control in tight spaces. Remember, a small oversight in selection could lead to operational challenges later on. Select wisely to avoid future complications.

How to Choose Heavy Castor Wheels for Your Industrial Needs?

| Factor | Description | Considerations |

|---|---|---|

| Load Capacity | The maximum weight the caster can support. | Ensure the total load does not exceed the manufacturer's recommendations. |

| Wheel Material | The material used to construct the wheel, affecting durability and floor compatibility. | Select materials such as rubber, polyurethane, or metal based on the environment and surface. |

| Wheel Diameter | The diameter of the wheel, which affects rollability and load handling. | Larger diameters provide smooth rolling over uneven surfaces. |

| Swivel vs Rigid | Swivel wheels can rotate 360 degrees, while rigid wheels are fixed. | Consider the maneuverability needs of your application. |

| Braking Mechanism | Mechanism that stops the wheel from rotating. | Assess safety requirements and choose a suitable braking system. |

| Environmental Resistance | Resistance to elements like moisture, chemicals, and extreme temperatures. | Select wheels designed for specific environmental conditions. |

Understanding Load Capacity: Choosing the Right Weight Rating

Choosing the right heavy castor wheels involves understanding load capacity. The weight rating is crucial for safety and efficiency. Many industrial environments require precise calculations. Research shows that improper load ratings can lead to accidents or equipment failure. According to the American Society for Testing and Materials (ASTM), a wheel should support at least 10% more than its maximum load.

Consider the total weight of items transported. For example, if you are moving a 1,000-pound load, select wheels rated for at least 1,100 pounds. This buffer accounts for unexpected dynamic loads. Industrial reports indicate that up to 30% of businesses face challenges when their wheels do not meet weight standards.

Regular inspection of castor wheels is essential. Damaged or worn-out wheels can compromise load capacity. Many users overlook this aspect, leading to increased downtime. A history of incidents suggests that even minor imperfections can disrupt operations. Revising load capacity requirements periodically can prevent such issues. Assessing these factors carefully contributes to better long-term performance.

Heavy Castor Wheels - Load Capacity Comparison

Materials and Durability: Assessing Wheel Composition for Longevity

When selecting heavy castor wheels, the materials used play a crucial role in determining their durability. Different compositions affect not only lifespan but also performance under various conditions. Common materials include rubber, polyurethane, and metal. Each has its strengths and weaknesses. Rubber wheels, for example, excel in shock absorption but may wear down quickly when exposed to heat.

Considering environmental elements is key. If your wheels will face moisture, choose materials resistant to rust. Polyurethane offers excellent resistance to chemicals and abrasion, making it a popular choice for industrial settings. However, if you're on a tight budget, you might compromise on durability with cheaper alternatives. This could lead to frequent replacements, ultimately costing more down the line.

Tips: Inspect the wheels under real-world conditions before settling on a choice. Testing can reveal flaws that a simple visual assessment might miss. Remember to evaluate the weight capacity of each wheel. Many users overlook this aspect, but exceeding weight limits can lead to premature failure. Take the time to research and ensure you're making the right decision.

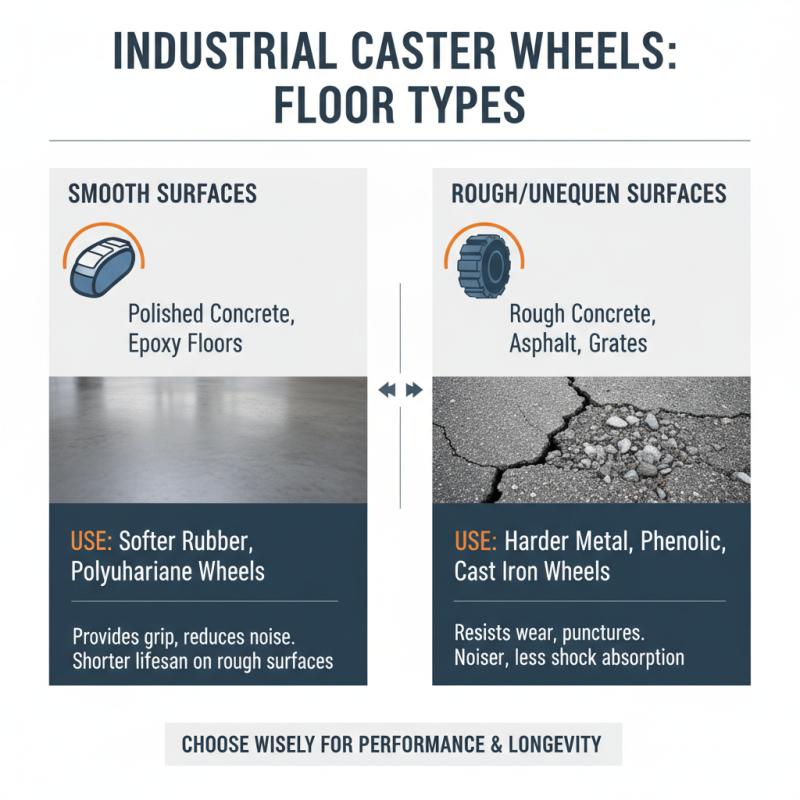

Surface Conditions: How Floor Types Impact Wheel Selection

When selecting heavy castor wheels for industrial use, consider the floor types where they will operate. The nature of the surface greatly influences the wheel's performance and longevity. Smooth surfaces require different wheels than rough or uneven terrains. On smooth concrete, softer wheels can work well, but they might wear out faster on abrasive surfaces.

**Tip:** Always inspect the floor condition. Small cracks or uneven patches can affect wheel choice. Don’t overlook these details.

For carpets, choose wheels designed specifically for soft surfaces. Standard wheels may sink and become stuck. In contrast, a rough terrain needs robust wheels. These wheels are designed to handle heavy loads without excessive wear.

**Tip:** Test your wheels under real conditions before full deployment. This helps identify potential issues.

When choosing the wheel's diameter, think about the load and travel distance. Larger wheels roll easier over obstacles. They are better for long distances, but don’t forget about storage space. Balance is key, and an incorrect size can lead to inefficiencies.

**Tip:** Reflect on your layout and workflow. Is there enough space for larger wheels?

Wheel Size and Design: Maximizing Maneuverability and Stability

Choosing the right heavy castor wheels is crucial for industrial efficiency. Wheel size plays a significant role in maneuverability. Smaller wheels are easier to turn but may struggle over uneven surfaces. Larger wheels can handle tough terrain and provide better stability. However, they can be cumbersome in tight spaces. It's essential to find a balance that suits your work environment.

Design also affects functionality. A wider wheel base enhances stability, reducing the risk of tipping. Swivel wheels offer flexibility, but they can be harder to control. Fixed wheels, on the other hand, provide straight-line movement but may require more effort to steer. Consider the layout of your workspace. Tight corners may need more articulation than open areas.

Reflecting on your needs is important. Calculate the load capacity required to avoid premature wear. Sometimes, the wrong choice can lead to frequent replacements. Assess your daily operations to pinpoint challenges. Will you regularly encounter ramps or inclines? The right wheel should navigate these obstacles smoothly. Understanding your unique situation is the key to making an informed decision.

Related Posts

-

The Comprehensive Guide to Sourcing Superior Vintage Steel Casters from Top Manufacturers

-

10 Reasons Why Best Vintage Steel Casters are Essential for Your Business Success

-

Why Choose Iron Castor Wheels for Your Heavy Duty Equipment Needs

-

How to Choose the Right Cast Iron Casters for Your Heavy-Duty Projects

-

Top Swivel Plate Casters: Choosing the Best for Your Project Needs

-

What is Caster Swivel and How It Enhances Mobility for Your Furniture