Essential Tips for Choosing the Right Iron Castors

Selecting the right Iron Castors can significantly impact your machinery and furniture performance. Industry reports indicate that over 30% of equipment failures are linked to inadequate casters. Optimizing caster choice not only enhances mobility but also extends the lifespan of your assets.

When considering Iron Castors, focus on factors such as load capacity and wheel size. Data shows that mismatched casters can lead to safety hazards and increased operational costs. Many users overlook these aspects and face unnecessary downtime and repairs.

It's crucial to assess the environment where the casters will be used. Factors like surface type and temperature can affect performance. Often, users choose based on aesthetics rather than function. Reflecting on these choices can lead to more informed decisions.

Understanding Iron Castors: Types and Materials

When selecting iron castors, understanding their types and materials is crucial. Iron castors come in various designs, each suited for specific tasks. The most common types include rigid castors, which provide stability, and swivel castors, allowing for easy maneuverability. Rigid castors work well on straight paths. Swivel castors excel in tight spaces.

Materials play a significant role in performance. Iron castors are often made with different finishes. A raw iron finish offers a rustic look but may rust easily. Powder-coated options are more resistant to corrosion. Consider the environment where the castors will be used. Wet or humid settings require special care.

Choosing the right castor isn't always straightforward. Sometimes, a castor may look perfect but perform poorly under load. Testing load limits is essential. Pay attention to wheel size, as larger wheels easier roll over obstacles. In some cases, lighter materials might be overlooked, limiting options. Reflecting on these details can lead to a more informed decision.

Key Factors Influencing Iron Castor Selection

Choosing the right iron castors is crucial for various applications. One major factor is load capacity. Consider the weight the castor will support and its frequency of use. If it's for heavy machinery, opt for sturdier options. However, oversizing can lead to unnecessary costs. Finding a balance is essential.

Another key aspect is the environment. Will the castors face wet conditions or abrasive surfaces? Different finishes and materials resist corrosion better. However, selecting the wrong type can lead to premature wear. Assessing the environment is vital, and sometimes, it’s easy to overlook critical details.

Finally, observe the style and design of the castors. Will they fit seamlessly with your equipment? Some designs may look great but might not function as needed. Test out various models if possible. This process may reveal unexpected surprises and help refine your choices. Often, it’s these small details that make a big difference.

Essential Tips for Choosing the Right Iron Castors - Key Factors Influencing Iron Castor Selection

| Factor | Description | Considerations |

|---|---|---|

| Load Capacity | The maximum weight an iron castor can support without failure. | Ensure the total load exceeds the castor’s rated capacity for safety. |

| Wheel Size | Diameter of the wheel affects mobility and surface compatibility. | Larger wheels roll easier over obstacles but may require more space. |

| Material | The type of material can affect performance and durability. | Consider rubber tire for softer floors, metal for heavy-duty applications. |

| Mounting Type | Configuration for attaching the castor to furniture or equipment. | Check compatibility with existing setups (plate, stem, etc.). |

| Brake Mechanism | Features to keep the castor from rolling inadvertently. | Choose locking brakes for stability in stationary positions. |

| Environmental Conditions | Conditions where the castors will be used (indoor, outdoor, wet, dry). | Select weather-resistant materials for outdoor use. |

Industry Standards and Regulations for Castor Design

When selecting iron castors, understanding industry standards is crucial. These regulations ensure optimal performance and safety. Each castor must meet specific load ratings. This is determined by the materials used in its construction. Regular assessments of these materials are essential for durability. A castor made from lower-quality iron may fail under pressure.

Furthermore, the design of the castor impacts its functionality. Different environments require varying features, such as weather resistance. Some castors are designed for smooth surfaces, while others excel on rough terrains. Choosing the right design means considering where the castor will be used. It is vital to evaluate whether to prioritize heavy duty or light mobility.

Many may overlook maintenance, but it's key for longevity. Regular checks can spot wear and tear before issues arise. Iron castors are not immune to rust if exposed to moisture. Proper care can enhance lifespan, but not everyone commits to this. Reflecting on these details can lead to better choices and improved performance in the long run.

Load Capacity and Performance Metrics in Iron Castors

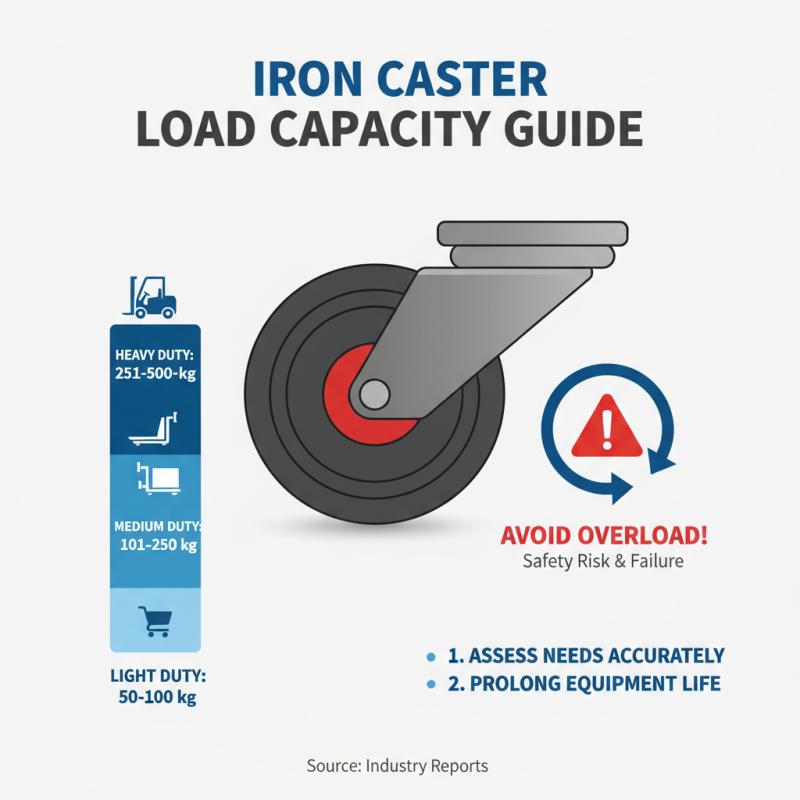

When selecting iron castors, load capacity is a vital consideration. Industry reports indicate that iron castors can support loads ranging from 50 kg to over 500 kg. This broad capacity range means you need to assess your specific requirements accurately. Overloading a castor can lead to premature wear or failure, resulting in potential safety hazards.

Consider the environment where the iron castors will be used. Will they face moisture, dirt, or heavy impact? Different materials can enhance performance under varied conditions. For instance, using castors with rubber treads can provide better shock absorption. Regular maintenance is crucial for enhancing longevity.

Tip: Assess how often the castors will be moved and the surfaces they’ll traverse. This evaluation helps in choosing the right wheel design. Remember, not all castors are built for heavy-duty tasks. Misjudging load requirements can lead to costly replacements. So, always refer to detailed load ratings before making your purchase.

Maintenance Tips for Longevity and Optimal Functionality

When choosing iron castors, maintenance is crucial for longevity and optimal functionality. Regularly inspect your castors for any signs of wear or damage. Look for cracks, rust, or loose fittings. Cleaning them can prevent buildup that affects mobility. A simple wipe with a damp cloth keeps them looking new.

Lubrication is another key aspect. Apply high-quality lubricant to the rotating parts at least once a month. This reduces friction and improves performance. However, avoid over-lubricating, as it can attract dirt. Check for debris in the wheels often. Removing it can prevent future issues.

Temperature and environmental factors also play a role. Extreme heat or cold can affect the material's integrity. If neglected, your castors may not perform as expected. Consider storing your items away from harsh conditions. It’s easy to overlook these details, yet they can lead to significant setbacks over time.

Related Posts

-

How to Choose the Right Iron Castors for Your Industrial Needs

-

How to Choose the Right Iron Casters for Industrial Applications Based on Load Capacity

-

What is Iron Casters and How Are They Used?

-

Top 7 Tips for Finding the Best Iron Castors Manufacturer Globally

-

What are the Benefits of Using Iron Casters in Industrial Applications

-

Top 10 Essential Tips for Choosing the Best Iron Castors for Your Needs