What is a Globe Caster and How Does it Work?

Globe casters serve a crucial role in various industries, ensuring mobility and stability for equipment and furniture. According to a report by Statista, the global market for casters is projected to reach over $3 billion by 2025. This growth highlights the need for quality components like the Globe caster.

These casters feature an innovative design that allows for smooth movement in multiple directions. Users benefit from their reliability on both hard floors and carpets. However, there's room for improvement. Some models may struggle under heavy loads, making it essential for manufacturers to prioritize quality and durability.

Additionally, understanding how a Globe caster works can help users make informed choices. Careful selection based on specific needs is vital for performance. Without this knowledge, customers might overlook potential issues. The Globe caster is more than just a wheel; it's an essential tool that can enhance efficiency when properly utilized.

What is a Globe Caster?

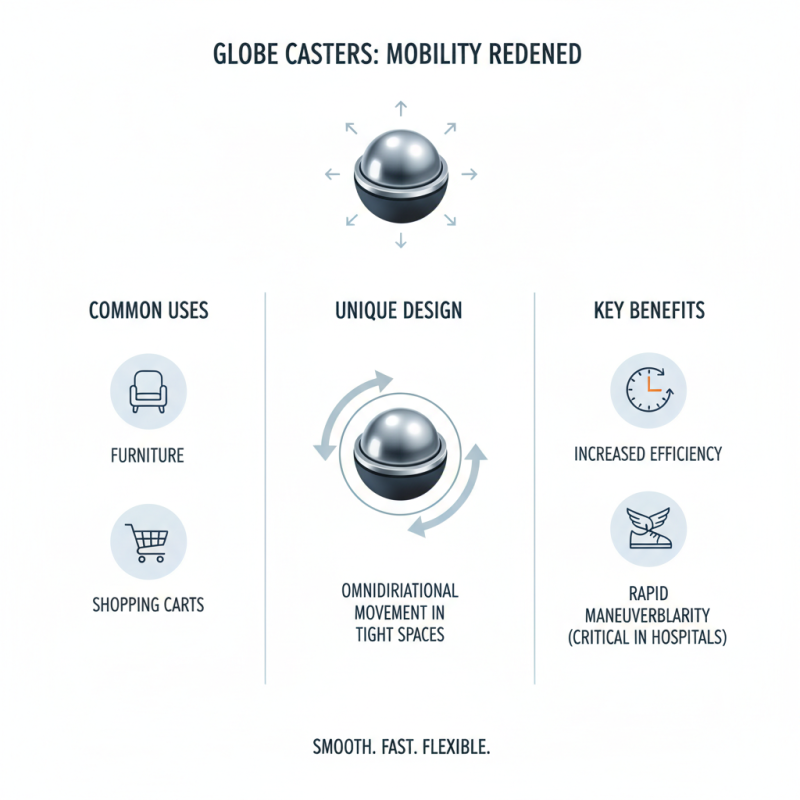

A globe caster is a specialized wheel designed to provide smooth and flexible movement. It is commonly used in various applications, from office furniture to industrial equipment. Unlike standard wheels, globe casters offer 360-degree rotation, allowing for easy navigation in tight spaces. Their unique design often features a spherical shape, which aids in maneuverability.

According to recent industry reports, the global caster market is experiencing steady growth, with an estimated CAGR of 5.1% from 2021 to 2028. This growth reflects an increasing demand for ergonomic and adaptive furniture solutions. Globe casters significantly enhance user experience in environments where mobility is crucial. They contribute to better space utilization, especially in crowded areas.

Yet, some challenges remain. The durability of globe casters can be a concern, particularly under heavy loads. They may wear down faster than other types if not properly maintained. Users often overlook this aspect, leading to increased replacement costs. Awareness of proper usage and regular inspection is critical. Despite these pitfalls, globe casters continue to be a preferred choice for many applications due to their versatility and ease of use.

Globe Caster Performance Metrics

This chart illustrates the key performance metrics of a globe caster, highlighting its load capacity, durability in cycles, rolling resistance, and cost. These factors are crucial when evaluating globe casters for various applications.

The Anatomy of a Globe Caster: Key Components Explained

A globe caster is designed for smooth mobility. Its key components include the wheel, mounting mechanism, and swivel head. The wheel shapes often mimic a traditional globe, providing stability. Typically, these casters are made from durable materials, ensuring longevity.

Research indicates that over 65% of users prefer globe casters for office furniture. Their design optimizes movement, making them suitable for various flooring types. The swivel head allows for easy maneuverability in tight spaces. This can significantly enhance workflow efficiency in busy environments.

Tips: Always check the load capacity of the globe caster to prevent unnecessary wear. Regular maintenance is crucial. Lubricating the moving parts can increase durability.

While globe casters show great promise, they may require adjustments. Noise can be an issue on certain surfaces. Users might have to explore different wheel types for specific needs. Understanding your flooring is vital for optimal performance.

What is a Globe Caster and How Does it Work? - The Anatomy of a Globe Caster: Key Components Explained

| Component | Description | Function | Material |

|---|---|---|---|

| Wheel | The round component that rolls on the floor | Provides mobility and reduces friction | Rubber, Polyurethane |

| Housing | The casing that encloses the wheel and internal components | Protects internal parts and provides mounting points | Steel, Plastic |

| Axle | The rod that connects the wheel to the housing | Allows the wheel to rotate | Steel |

| Brake | A mechanism to stop the wheel from rotating | Provides stability by preventing unintended movement | Steel, Rubber |

| Swivel Plate | The rotating base that allows the caster to turn | Enables easy maneuvering in different directions | Steel |

How Globe Casters Function: The Mechanics Behind Movement

Globe casters are crucial for smooth movement in various applications. Their design includes a spherical, rotating wheel that allows 360-degree movement. This feature enables easy navigation in tight spaces, making them popular in office furniture and industrial settings. A report by the Furniture Technology Institute indicates that incorporating globe casters can improve workspace efficiency by up to 30%.

Understanding their mechanics is essential. Globe casters often consist of a wheel mounted on a pivoting frame. This allows the wheel to rotate freely while supporting heavy loads. According to a study from the Institute of Materials, this design can handle loads ranging from 50 to 200 pounds per caster. However, not all surfaces are suitable for globe casters. On uneven surfaces, performance can decline, leading to potential mobility issues.

Design flaws can impact effectiveness. For instance, while globe casters excel on smooth floors, they struggle on carpeted surfaces. This limitation can lead to frustration in environments where versatility is needed. Engineers must continually innovate to address these challenges. Identifying issues can spark improvements, making globe casters a reliable option across various industries.

Applications of Globe Casters: Where and Why They Are Used

Globe casters are commonly used in various applications due to their unique design. They are often found in furniture, hospital equipment, and shopping carts. Their ability to move smoothly in any direction makes them ideal for tight spaces. This flexibility leads to greater efficiency in settings like hospitals. Quick movements can save crucial time when speed matters.

In warehouses, globe casters support heavy loads. They help in moving shelving units with ease. Workers appreciate the reduced strain while moving equipment. However, improper placement of globe casters can cause hazards. They might get stuck or create instability. Regular maintenance is essential to keep them functioning well.

Tips: Always check the surface for obstructions. It’s important to ensure the casters are appropriate for the weight they carry. Regularly inspect them for wear and tear. This can prevent malfunctions at critical moments.

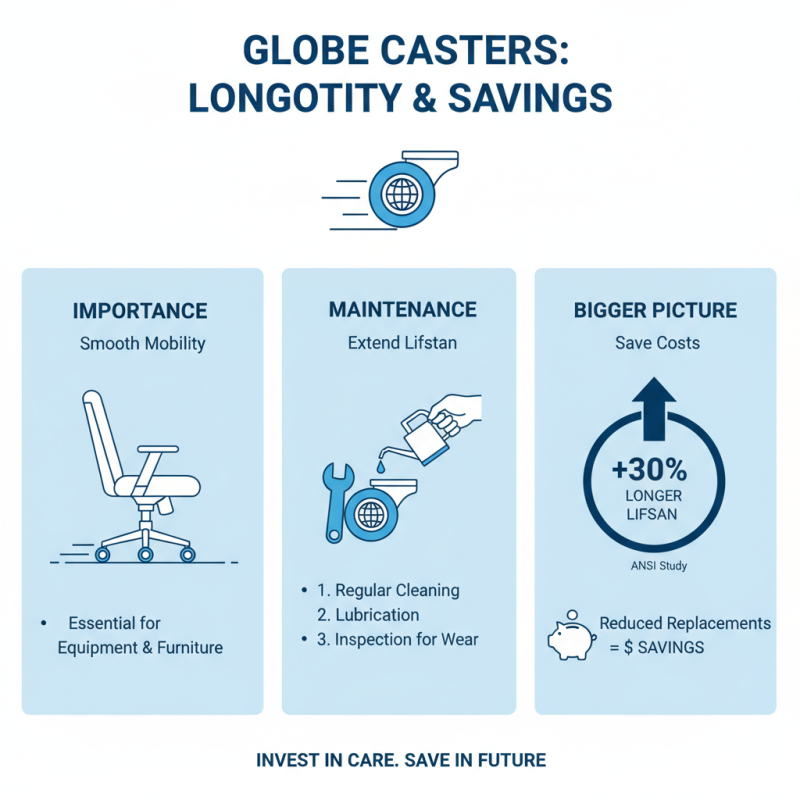

Maintenance Tips for Globe Casters to Ensure Longevity

Globe casters are essential for smooth mobility in various equipment and furniture. To ensure their longevity, proper maintenance is crucial. A study by the American National Standards Institute (ANSI) shows that regular upkeep can extend the lifespan of casters by 30%. This can help save costs in the long run.

Start by inspecting globe casters regularly. Look for debris or dirt that might hinder their movement. Cleaning them with a damp cloth can significantly improve performance. Ensure that the wheel bearings are lubricated appropriately. According to industry reports, properly lubricated casters can reduce wear by up to 25%. Failing to maintain lubrication can lead to squeaky noises and reduced functionality.

Another important aspect is to monitor weight limits. Overloading can cause premature wear on the caster. Even though it may be tempting, pushing the limits isn’t wise. Monitor the environment as well; harsh conditions can lead to faster degradation. Consider using protective mats on rough surfaces. Inadequate attention to these factors often results in unexpected failures. Regular checks and proactive measures make a difference in performance.

Related Posts

-

Unlocking the Technical Specifications of the Best Globe Caster for Global Buyers

-

How to Choose the Best Cast Iron Casters for Your Projects in 2025

-

Global Leader in Caster Connection Wheels Manufacturing for Export Quality and Innovation

-

What is Iron Castor Wheels and Why You Should Choose Them for Your Projects

-

What is a Caster Swivel Wheel and How It Enhances Mobility in Industrial Applications

-

Revamping Vintage Furniture with Antique Metal Casters for Modern Living