What is Iron Casters and How Are They Used?

Iron Casters play a significant role in various applications. These small but mighty items support furniture movement with ease. Often made from durable materials, Iron Casters ensure durability and longevity. They are widely found on chairs, tables, and carts.

In today's world, the need for mobility in furniture is undeniable. Iron Casters provide a practical solution. They help move heavy pieces with minimal effort. This functionality is essential, especially in busy environments like offices or homes. However, not all Iron Casters are created equal. Choosing the right type can be challenging, and improper use may lead to damage.

Reflecting on their use, one must consider weight capacity and surface types. Not considering these factors might result in accidents. It's vital to match Iron Casters to specific needs. Understanding their role is essential for effective use.

What Are Iron Casters?

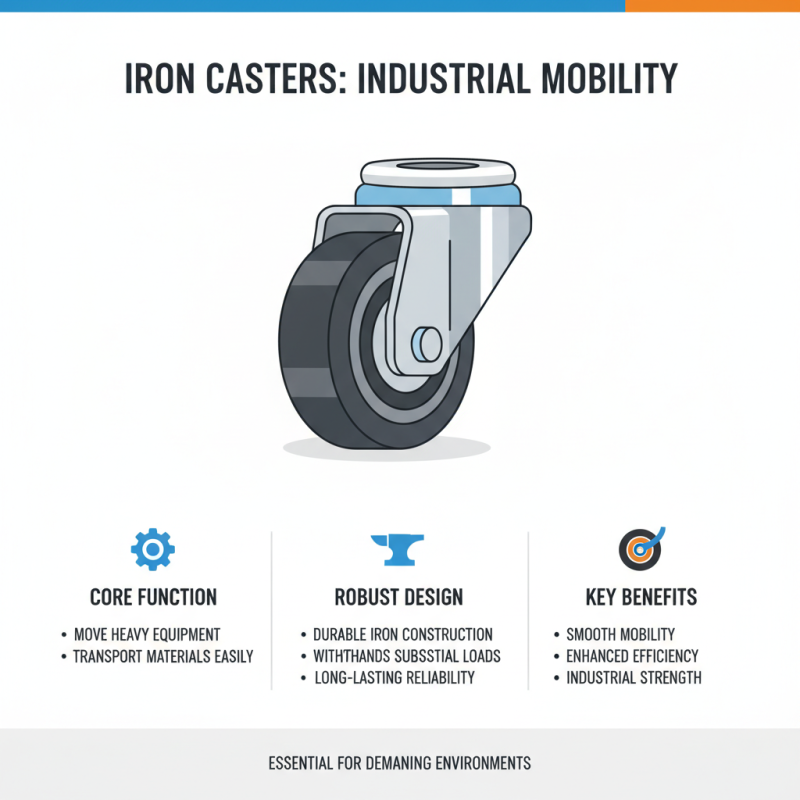

Iron casters are essential tools in various industries, aiding in the movement of heavy equipment and materials. They are designed to support the weight of items while allowing for smooth mobility on floors. These casters typically feature a sturdy wheel system made from durable iron, which can withstand substantial loads. The construction ensures longevity and reliability in demanding environments.

The design of iron casters varies greatly. Some feature a swivel mechanism, allowing easy navigation in tight spaces. Others are fixed, providing straight-line movement. Factors such as wheel diameter and load capacity vary widely. This diversity allows users to select casters for specific applications, whether in warehouses or workshops. However, choosing the right type requires careful consideration of weight and surface types.

Not all iron casters perform equally well on different surfaces. Some may struggle on uneven floors, leading to frustrating malfunctions. Additionally, rust can develop on exposed parts if not properly maintained. Users often overlook these maintenance needs, leading to larger issues. Balancing durability and care is crucial for consistent performance.

The History of Iron Casting Techniques

Iron casting has a rich history that dates back thousands of years. It began in ancient China around the 5th century BCE. Artisans discovered that pouring molten iron into molds could create strong and durable tools. This technique slowly spread to other cultures, like the Romans, who further refined the process.

Over time, various casting methods emerged. The sand casting technique became popular during the Middle Ages. Craftsmen used sand to create molds, making it easier to produce complex shapes. This method is still widely used today. Casting also allowed for mass production of items, such as cookware and machinery parts. Yet, some early techniques had limitations. They often resulted in defects and inconsistencies.

By the 19th century, advancements in technology transformed the industry. The introduction of molten iron from blast furnaces improved quality. However, these changes weren't perfect. Some foundry workers faced challenges adapting to new machinery. Despite this, the evolution of iron casting laid the foundation for modern manufacturing. Today, we see its impact in countless everyday products.

Key Applications of Iron Casters in Industries

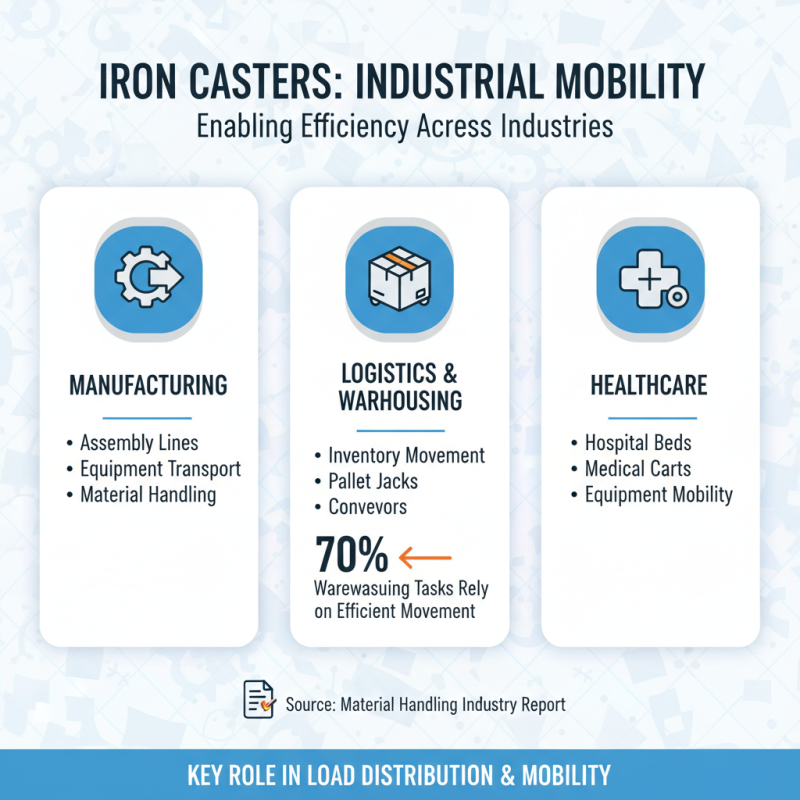

Iron casters play a vital role in various industries. They are crucial for mobility and load distribution in manufacturing, logistics, and healthcare settings. According to a report by the Material Handling Industry, about 70% of warehousing tasks rely on efficient movement solutions. Iron casters facilitate this by enabling easy transportation of heavy items.

In manufacturing, iron casters are commonly found on assembly lines and machinery. They provide stability and support for heavy equipment. This not only aids in production efficiency but also enhances worker safety. The industrial sector has shown a rise in painted iron casters due to their durability and resistance to wear. Reports indicate that businesses can reduce maintenance costs by approximately 25% when using high-quality casters.

Healthcare facilities also utilize iron casters. Hospital beds and medical equipment often rely on these components for easy mobility. However, the challenge lies in ensuring that these casters meet both strength and hygiene standards. Many healthcare environments struggle with the balance between functionality and cleanliness. This gap may lead to increased infection risk, prompting ongoing reassessment of industry standards.

Types of Iron Casters and Their Features

Iron casters are essential components in various manufacturing and industrial applications. They provide mobility to heavy machinery and equipment. Understanding the different types of iron casters can help businesses optimize their operations.

There are several types of iron casters. Each type has unique features and capabilities. For instance, rigid casters are known for their durability. They can support heavy loads and are often used in factories. According to a recent industry report, nearly 40% of manufacturers prefer rigid configurations for stability. Swivel casters, on the other hand, offer greater maneuverability. They can pivot and change direction easily, making them ideal for tight spaces.

Another notable type is the locking caster. This design includes a brake mechanism. It can hold equipment securely in place, which is crucial for safety. Some reports indicate that the use of locking casters has increased by 25% in the past five years. This surge reflects a growing awareness of workplace safety. However, some users still encounter issues with improper installation. Iron casters need regular maintenance to ensure optimal performance. Relying solely on one type of caster may not meet all operational needs. Diversifying can lead to better outcomes.

What is Iron Casters and How Are They Used? - Types of Iron Casters and Their Features

| Type of Iron Caster | Material Used | Load Capacity (lbs) | Features | Common Applications |

|---|---|---|---|---|

| Standard Iron Caster | Cast Iron | 450 | Durable, heavy-duty, good for rough surfaces | Furniture, heavy equipment |

| Swivel Iron Caster | Cast Iron with Zinc Plating | 350 | 360-degree rotation, easy maneuverability | Shopping carts, mobile workstations |

| Brake Iron Caster | Cast Iron | 500 | Includes brake for stability | Industrial carts, tool storage |

| Heavy-Duty Iron Caster | Ductile Iron | 1000 | High strength, resistant to impacting and deforming | Construction equipment, heavy machinery |

Advantages and Limitations of Using Iron Casters

Iron casters are a popular choice for various applications. They are widely used in furniture, carts, and industrial equipment. Their sturdy construction provides stability and durability.

Advantages include their strength and load-bearing capacity. Iron casters can support heavy weights without bending. This makes them ideal for heavy-duty applications. The aesthetic appeal of iron also adds a vintage charm.

However, there are limitations. Iron can be heavy, which may not suit all designs. Its weight can make movement more difficult. Additionally, iron is prone to rust. This can be a concern in humid environments. Regular maintenance is necessary to prolong their life.

Tips: To prevent rust, consider a protective coating. This can shield iron from moisture. Regularly check for signs of wear and tear. Early intervention can save money in the long run. Finally, match the caster size to your needs. This ensures optimal performance.

Advantages and Limitations of Using Iron Casters

Related Posts

-

How to Choose the Right Iron Castors for Your Industrial Needs

-

What are the Benefits of Using Iron Casters in Industrial Applications

-

How to Choose the Right Iron Casters for Industrial Applications Based on Load Capacity

-

Top 10 Iron Casters: Features, Benefits, and FAQs Explained

-

How to Choose the Best Iron Castor Wheels for Your Needs

-

What Are the Key Features of Caster Trolley Wheels