Top 10 Iron Casters: Features, Benefits, and FAQs Explained

When it comes to furniture and equipment, choosing the right components is essential. Iron casters are a popular choice for many applications. Their durability and strength make them ideal for heavy loads. Additionally, they offer a smooth and quiet movement, enhancing the overall experience of use. However, not all iron casters are created equal.

With various features and specifications, it's important to find the best fit for your needs. Factors such as wheel size, weight capacity, and design can greatly influence performance. While many may focus solely on price, quality and reliability often deserve equal consideration.

In the world of iron casters, there are many options available. Understanding these choices may require some effort. There's a mix of information that might seem overwhelming. A careful examination can lead to better selections and smarter purchases. Exploring the top options helps navigate this complexity while addressing common questions. Overall, the right iron caster can make a significant difference in functionality and longevity.

Top Features of Iron Casters: Material Composition and Durability

Iron casters are essential in many industries. Their material composition and durability significantly impact performance. Typically made from cast iron, these casters offer excellent load-bearing capabilities. According to a 2022 industry report, cast iron casters can withstand pressures of up to 1,500 pounds per wheel. This makes them ideal for heavy-duty applications.

The durability of iron casters is noteworthy. They resist wear and tear, making them suitable for long-term use. A study found that cast iron casters last 25% longer than their plastic counterparts. However, they are not immune to damage. Over time, they can chip or crack under extreme conditions. Adequate maintenance is crucial.

Another factor to consider is environmental impact. Iron production releases significant CO2 emissions. Eco-conscious users may prefer alternative materials. While iron casters have strength, they might not be the best choice for every setting. Observing real-world applications can provide insights into their effectiveness.

Benefits of Using Iron Casters in Industrial Applications

Iron casters are essential in many industrial applications. Their ability to withstand heavy loads is impressive. They are known for their durability and strength. This makes them ideal for moving heavy equipment. Factories and warehouses often rely on these casters for smooth operations. They are designed to handle rough terrain and provide stability.

One interesting feature is the resistance to wear and tear. Iron casters won't break down easily. However, they can be heavy, making some setups challenging. It’s crucial to assess the weight limits of the casters. Misjudging this can lead to complications. Another benefit is their resistance to heat. This is important for environments where temperature changes frequently.

Using iron casters also means managing potential downsides. They might be prone to rust if not properly maintained. Ensuring regular checks can prevent long-term issues. Choosing the right type based on the environment is key. A good decision can enhance productivity. If issues arise, it’s time to rethink the approach.

Top 10 Iron Casters: Features, Benefits, and FAQs Explained - Benefits of Using Iron Casters in Industrial Applications

| Caster Type | Load Capacity (lbs) | Wheel Diameter (in) | Material | Benefits |

|---|---|---|---|---|

| Heavy Duty Iron Caster | 1200 | 6 | Iron | High strength, excellent durability |

| Swivel Iron Caster | 800 | 5 | Iron | Maneuverability, smooth rolling |

| Rigid Iron Caster | 1000 | 8 | Iron | Stable, ideal for straight-line transport |

| Iron Caster with Brake | 700 | 4 | Iron | Safety, prevents unwanted movement |

| Corrosion Resistant Iron Caster | 900 | 7 | Iron with protective coating | Longer lifespan, suitable for humid environments |

| Industrial Iron Caster | 1500 | 9 | Iron | Designed for heavy machinery and equipment |

| Anti-static Iron Caster | 600 | 5 | Iron | Prevents static buildup, ideal for electronics |

| Steel Frame Iron Caster | 1100 | 6 | Iron with steel frame | Enhanced strength and support |

| Heavy Load Iron Caster | 2000 | 10 | Iron | Supports extremely heavy loads, robust design |

| Multi-directional Iron Caster | 750 | 5 | Iron | Allows movement in multiple directions |

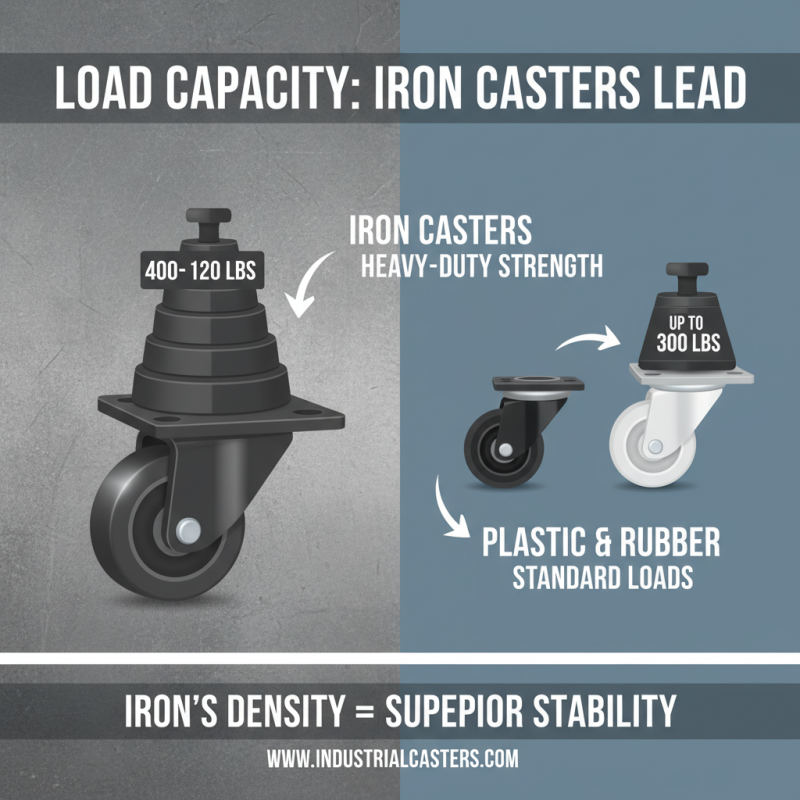

Comparison of Load Capacity: Iron Casters vs. Other Materials

When comparing load capacity, iron casters stand out among other materials. Industry reports indicate that iron casters can typically support between 400 to 1,200 pounds. This heavy-duty capability often exceeds that of plastic or rubber casters, which usually only carry loads up to 300 pounds. The difference in material strength is significant. Iron's density and solid construction provide stability.

However, weight is a factor. Iron casters are heavier and may hinder mobility. Many users have noted that they can be cumbersome during transportation. In contrast, lighter materials offer ease of movement but sacrifice strength. This trade-off is crucial for businesses requiring both support and flexibility.

Additionally, iron casters are more prone to rusting and corrosion if not properly maintained. This requires a careful balance of load capacity and maintenance considerations. Regular checks and protective coatings might mitigate degradation, but this process can be time-consuming. Ultimately, understanding the specific needs for load capacity can guide the choice between iron and alternative materials.

Common FAQs About Iron Casters: Maintenance and Performance

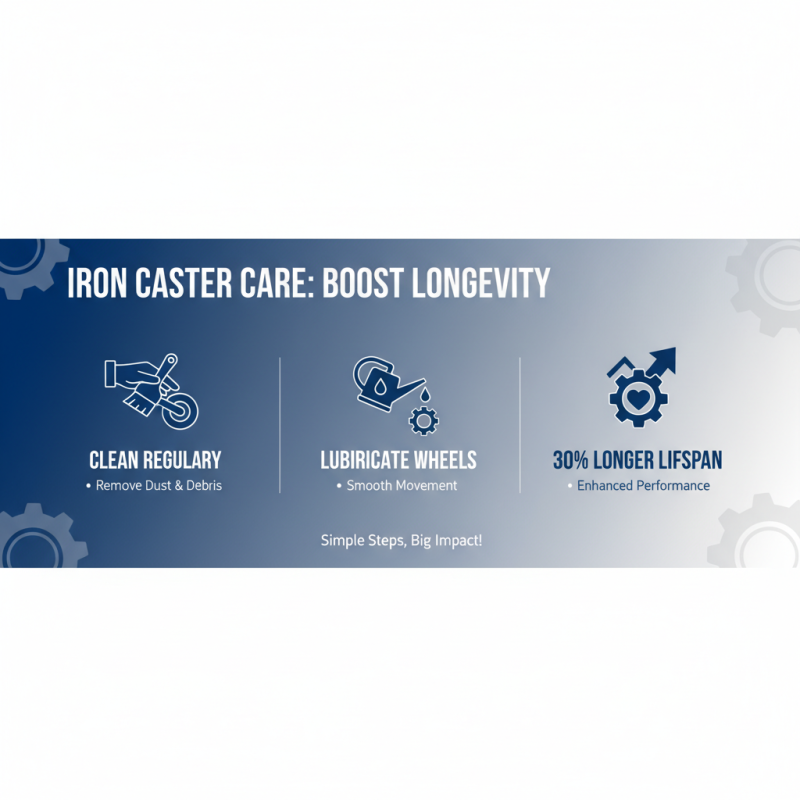

When it comes to iron casters, maintenance is crucial. Regular care affects performance and longevity. Studies show that proper upkeep can extend the life of a caster by 30%. Simple actions, such as cleaning and lubricating wheels, can make a significant difference. Dust and debris can hinder movement, causing wear over time.

Check the wheels for signs of damage regularly. Look for cracks or chips that can impact performance. Replacing worn-out components helps maintain efficiency. Often, users overlook this basic step. When wheels don't roll smoothly, it leads to strain on equipment and operators.

Tip: Always use a soft cloth to clean casters. Avoid harsh chemicals that could damage the finish. Furthermore, store equipment in a dry area to prevent rust buildup. Moisture can severely diminish the performance of iron casters. Use a silicone spray to keep wheels rolling effortlessly. This simple step enhances mobility and reduces friction.

Market Trends: The Demand for Iron Casters in Manufacturing Industries

The demand for iron casters in manufacturing industries is on the rise. These components are vital for a range of applications. They provide durability and stability in various machinery. As industries evolve, the need for high-quality casters becomes more pronounced. Manufacturers seek robust solutions that can withstand heavy loads.

Market trends indicate an increasing focus on innovation. Companies are exploring advanced materials and designs. There’s a noticeable shift toward sustainability, too. Many businesses are prioritizing eco-friendly manufacturing processes. However, challenges persist. Traditional methods may lag behind modern requirements. The balance between cost and quality continues to be a point of contention.

The competitive landscape is also changing. New players are entering the market, and innovation is essential. Manufacturers must adapt swiftly to stay relevant. Consumers are looking for both price and performance. As iron casters improve, the feedback loop from users offers valuable insights. It’s crucial to listen to this input. The industry must strive for continuous improvement to meet growing demands.

Related Posts

-

What are the Benefits of Using Iron Casters in Industrial Applications

-

How to Choose the Right Iron Castors for Your Industrial Needs

-

Top 7 Tips for Finding the Best Iron Castors Manufacturer Globally

-

The Ultimate Guide to Sourcing the Best Antique Metal Casters for Your Projects

-

Understanding the Differences Between Swivel Plate Casters and Fixed Casters

-

The Science Behind Heavy Caster Wheels and Their Impact on Workload Efficiency