Top 10 Swivel Plate Caster Types for Your Needs?

In the world of logistics and manufacturing, choosing the right Swivel Plate Caster is crucial. Expert Anna Davis, a leading figure in material handling, once said, "The right caster can make all the difference in workflow efficiency." This highlights the importance of understanding different types of casters available in the market.

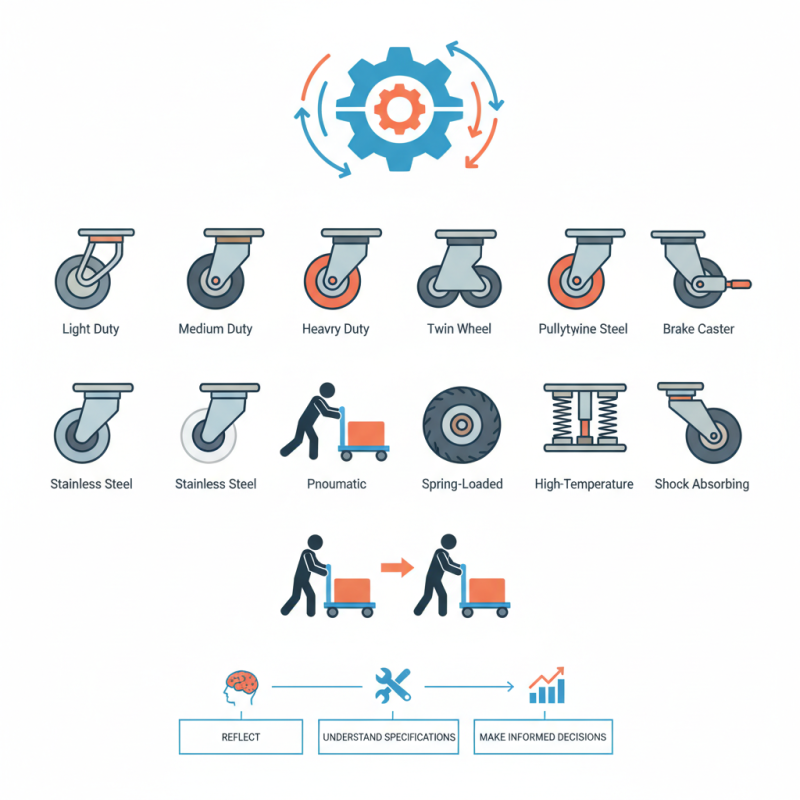

Swivel Plate Casters come in various forms. Each type serves a unique purpose. From light-duty applications to heavy-duty environments, knowing what suits your needs is essential. Not all swivel casters are created equal. Some may wear out quickly under heavy loads, while others excel in smooth movement.

Choosing poorly can lead to frustrating challenges. Imagine trying to move a cart with inadequate casters—it can be a nightmare. Take time to reflect on your specific requirements. Understanding caster specifications can lead to better performance and safety in workspaces. Make informed decisions to enhance efficiency in your daily operations.

Understanding Swivel Plate Casters and Their Applications

Swivel plate casters are essential for various applications. These casters offer exceptional mobility and versatility. They allow for smooth turns and easy navigation in tight spaces. Different types cater to diverse needs. From heavy-duty versions for industrial use to lighter ones for furniture, the options are numerous.

When selecting a swivel plate caster, consider the weight and surface type. The wheel material can affect performance. Rubber wheels provide a quiet ride, while hard plastic wheels can endure heavy loads. However, they may create noise. Ensure the caster is appropriate for your specific environment.

Assess the mounting options as well. Some casters come with brake systems. This feature prevents unwanted movement. You might also find swivel locks beneficial for stability. Reflecting on your requirements can lead to better choices. Balancing quality with your needs may take time, but it’s crucial for lasting performance.

Top 10 Swivel Plate Caster Types for Your Needs

| Caster Type | Wheel Material | Load Capacity (lbs) | Applications | Wheel Diameter (inches) |

|---|---|---|---|---|

| Standard Swivel Caster | Polyurethane | 350 | Furniture, Trolleys | 4 |

| Heavy Duty Swivel Caster | Rubber | 800 | Industrial Equipment | 6 |

| Locking Swivel Caster | Nylon | 500 | Workbenches, Carts | 5 |

| Rigid Swivel Caster | Metal | 600 | Heavy Storage Racks | 8 |

| Kingpinless Swivel Caster | Polyurethane | 700 | Medical Equipment | 5 |

| Threaded Stem Caster | Rubber | 400 | Office Chairs, Desks | 3 |

| Plate Caster | Plastic | 300 | Lightweight Furniture | 4 |

| Extra Wide Caster | Polyolefin | 500 | Heavy Load Distribution | 6 |

| ESD Safe Caster | Conductive Rubber | 400 | Electronics Manufacturing | 5 |

| Ultra Smooth Caster | Soft Polyurethane | 350 | Clean Rooms, Labs | 4 |

Key Factors to Consider When Choosing Swivel Plate Casters

When choosing swivel plate casters, several key factors should guide your decision. First, load capacity is critical. Casters are rated for specific weights. Overloading them can lead to failures. For instance, a report by Caster Research shows that over 20% of caster failures stem from exceeding weight limits. It’s essential to understand the weight of the objects you plan to move.

Wheel material is another important aspect. Different environments require different wheels. For example, rubber wheels work well on hard surfaces, while polyurethane offers durability on various terrains. Each material has its pros and cons. It’s easy to overlook this detail and end up with a caster that does not suit your needs.

Tip: Always consider the floor type where casters will roll. This ensures optimal mobility and longevity.

Lastly, swivel radius and mounting height matter. A larger swivel radius allows for easier maneuverability in tight spaces, while adjustable heights can help fit different applications. However, some designs may compromise stability. It’s a balancing act that requires careful thought.

Tip: Test samples before purchasing. Hands-on experience can unveil unanticipated issues. This approach minimizes future headaches.

Top Types of Swivel Plate Casters Suitable for Heavy Loads

When it comes to heavy loads, choosing the right swivel plate caster is crucial. These casters offer a seamless way to move hefty items. Key types include heavy-duty steel casters and polyurethane wheels. Steel casters provide robust support, while polyurethane minimizes floor damage and noise.

Tips: Always assess the load capacity before purchasing. Ensure the casters can support your equipment. Sometimes, the cheapest option may not be the best choice.

Look for casters designed specifically for heavy loads. Locking mechanisms can also add stability, especially on slopes. Casters with larger wheels roll easier over obstacles. However, they sometimes require more space for turning.

It's essential to consider the material and construction. Some casters might show wear sooner than expected. Regular inspections are vital to avoid mishaps. Pay attention to movement ease. Stiff casters can cause strain, impacting productivity. Make choices based on your specific needs to ensure safety and efficiency.

Best Suited Swivel Plate Casters for Residential Use

When choosing swivel plate casters for residential use, consider the

surface.

Hardwood floors need softer wheels. Hard wheels can scratch and damage surfaces. For carpeted areas, harder wheels provide better maneuverability.

Tips: Measure your furniture's weight. Choose casters that can support it well. A margin is always wise. It adds safety and longevity to your casters.

Material matters too. Rubber casters are quiet and absorb shocks. They glide smoothly over various surfaces. Metal wheels, on the other hand, are durable but may create noise. Reflecting on your daily needs is key.

Tips: Think about where you use these casters most. Will they often be moved? Is noise a concern for you? Tailor your choice based on these aspects. Too many overlook this. It’s essential for finding the right fit.

Innovative Features of Modern Swivel Plate Casters

Swivel plate casters have evolved with innovative features that enhance mobility and efficiency. Many modern designs now incorporate sealed bearings, which reduce friction and improve wheel durability. According to industry reports, casters with sealed bearings can extend product life by up to 25%. This is a significant advantage for businesses seeking long-term investments.

Additionally, the load capacity of swivel plate casters has improved. Heavy-duty models can now support loads exceeding 6,000 pounds. This advancement is essential for industries that rely on high-capacity equipment. However, it's crucial to choose the right size and type for specific applications to prevent premature failure.

Tip: When selecting casters, consider the floor surface where they'll be used. Soft wheels are perfect for delicate floors, while harder wheels work well on rugged surfaces. Not all casters are created equal, so assess your needs thoroughly.

Another innovative feature is the directional lock. This allows the user to keep the wheels moving in a straight line during transport. Such functionality is valuable in crowded work environments. However, some users overlook this feature, losing potential advantages. Evaluate your workspace carefully; these details matter more than they seem.

Top 10 Swivel Plate Caster Types

Related Posts

-

Global Leader in Caster Connection Wheels Manufacturing for Export Quality and Innovation

-

Exploring the Versatility of Swivel Plate Casters: Ultimate Guide to Choosing the Right Caster for Your Needs

-

What is Iron Castor Wheels and Why You Should Choose Them for Your Projects

-

How to Choose the Best Furniture Castor Wheels for Your Home or Office

-

Top 10 Furniture Castor Wheels for Smooth Mobility and Easy Movement

-

Top Swivel Plate Casters: Choosing the Best for Your Project Needs