Stainless Casters Types and Benefits What You Need to Know?

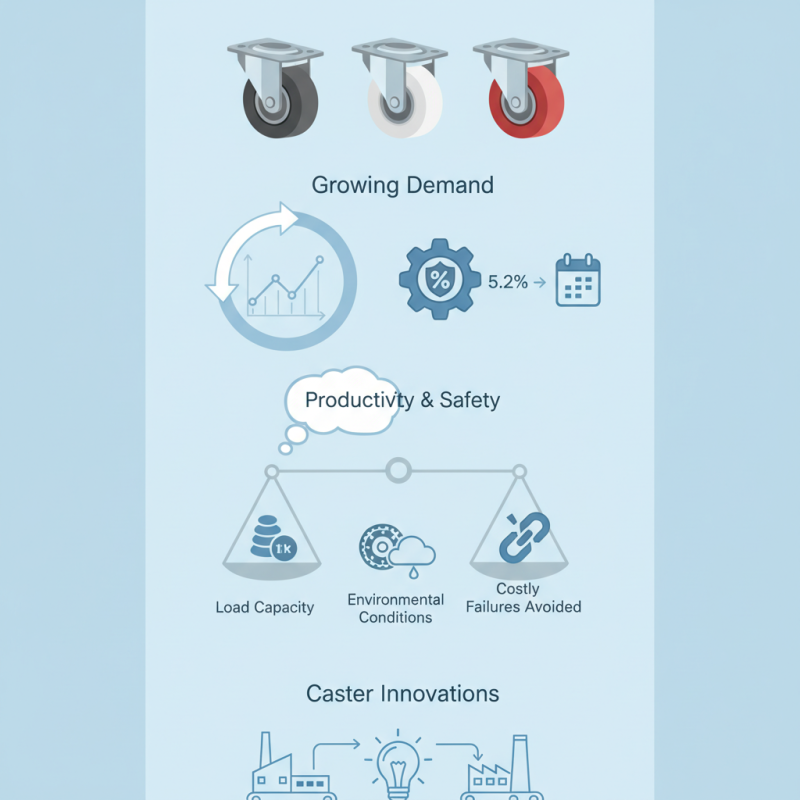

Stainless casters play a critical role in various industries, including manufacturing and logistics. According to a 2022 report by Market Research Future, the global stainless casters market is projected to grow by 5.2% annually. This growth highlights the increasing demand for durable and reliable solutions in heavy-duty applications.

Industry expert Dr. Emily Stanton remarks, "The right choice of stainless casters can significantly enhance productivity and safety." This insight emphasizes the importance of understanding caster types and their specific benefits. Many businesses still overlook the strengths of stainless casters. They are not just components; they can transform operational efficiency.

Choosing the correct stainless casters necessitates careful consideration. Factors like load capacity, wheel materials, and environmental conditions are crucial. Neglecting these aspects can lead to costly operational failures. As the market evolves, staying informed about caster innovations and their applications is essential for maximizing benefits in any workspace.

Types of Stainless Casters Available in the Market

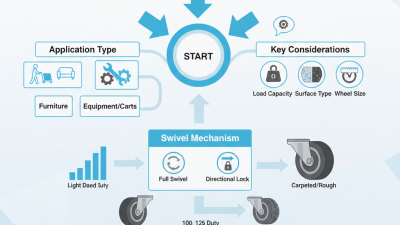

When it comes to stainless casters, several types are available to meet various needs. swivel casters allow for easy maneuverability. They pivot in a circle, making them ideal for tight spaces. On the other hand, rigid casters do not swivel and are perfect for straight-line motion. These two primary types serve different purposes, and each has its own benefits.

Material also matters. Stainless steel is resistant to rust and corrosion, enhancing the durability of casters. Some options include phenolic wheels for hard surfaces and rubber wheels for softer ground. Choosing the right wheel material can influence your equipment's performance.

Tips: Always consider the load capacity. It’s important not to exceed the weight limit. This can lead to premature wear or failure. Also, think about the environment where the casters will be used. Will they be on wet or uneven surfaces? These details matter. Investing time in selection can save money in the long run. It is worth spending time to understand your specific needs.

Key Benefits of Using Stainless Casters in Various Applications

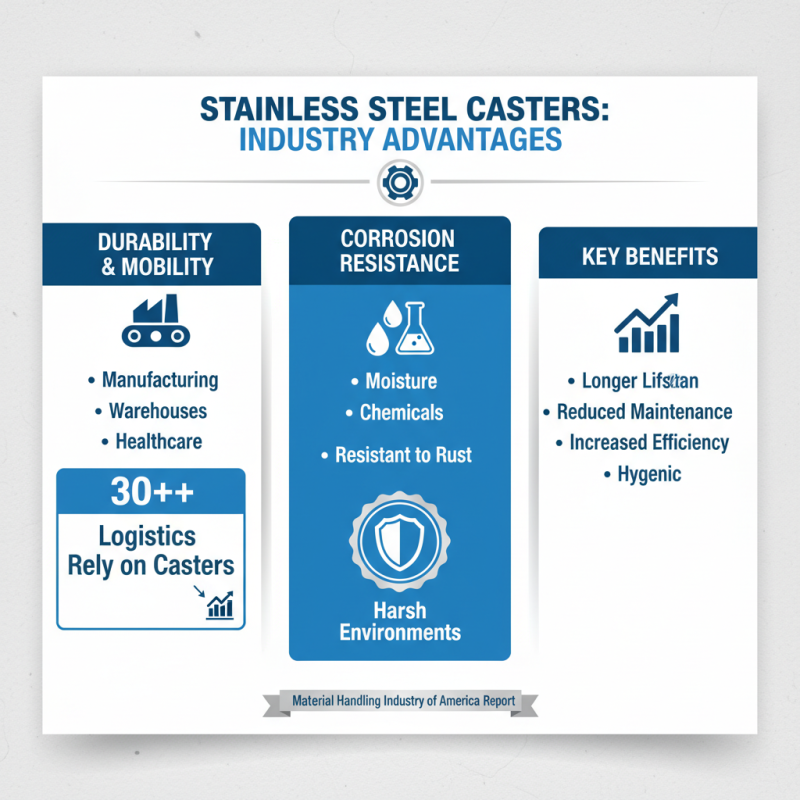

Stainless casters bring significant advantages across various industries. These durable components are commonly used in manufacturing, warehouses, and healthcare settings. A report from the Material Handling Industry of America shows that over 30% of logistics operations rely heavily on mobility solutions like casters. This is largely due to their corrosion resistance. In environments where moisture and chemicals are present, stainless steel casters stand out.

In the food processing industry, sanitation is paramount. Stainless casters can withstand rigorous cleaning protocols. They reduce the risk of contamination. A study indicates that using stainless casters can enhance hygiene standards, leading to fewer health violations. Moreover, their strength allows for safe movement of heavy equipment. This could lead to improved operational efficiency. In healthcare, the shift towards stainless casters is notable. They contribute to infection control efforts, significantly improving patient safety.

While the benefits are clear, not all applications will find stainless casters the best fit. They may be costlier than their plastic counterparts. In scenarios where heavy loads are not a concern, the expense might not be justified. Users should weigh the long-term benefits against upfront costs. Despite these considerations, the usability of stainless casters continues to grow in various sectors. Their unique properties make them a preferred choice for many.

Factors to Consider When Choosing Stainless Casters

When choosing stainless casters, several factors come into play. The environment where they will be used is crucial. Stainless steel is durable, making it suitable for harsh conditions. Consider the working surface. A softer surface may require wheels that distribute weight evenly and prevent damage.

The load capacity of the casters matters too. Ensure they can handle the weight of the items. Too often, people overlook this and face issues later. Another aspect is wheel size. Larger wheels can roll over obstacles easily, while smaller ones may struggle.

Finally, think about the swivel feature. Swiveling casters allow more maneuverability in tight spaces. Some users might find fixed options more stable, yet they can be limiting. Always reflect on your specific needs before deciding. Choices should not be made lightly.

Stainless Casters Types and Benefits What You Need to Know? - Factors to Consider When Choosing Stainless Casters

| Caster Type | Material | Load Capacity (lbs) | Wheel Diameter (inches) | Benefits |

|---|---|---|---|---|

| Swivel Casters | Stainless Steel with Polyurethane Wheel | 400 | 4 | High maneuverability and durability |

| Fixed Casters | Stainless Steel with Rubber Wheel | 500 | 5 | Great for heavy loads and stable movement |

| Brake Casters | Stainless Steel with Nylon Wheel | 350 | 4 | Prevents unwanted movement, enhanced safety |

| Heavy-Duty Casters | Stainless Steel with Polyolefin Wheel | 800 | 6 | Designed for extreme loads and tough environments |

Maintenance Tips for Enhancing the Longevity of Stainless Casters

When it comes to maintaining stainless casters, regular inspection is key. Look for any signs of rust or wear. A small chip can lead to bigger issues later. Also, check the wheel for debris. A simple cleaning can enhance performance.

Lubrication is another vital aspect. Use appropriate lubricants specifically for stainless steel. Over time, dirt and grime can accumulate. If left unchecked, this can affect movement. Apply lubricant periodically to keep the wheels rolling smoothly.

Lastly, consider the environment where the casters are used. Extreme temperatures and humidity can have adverse effects. While stainless steel is resistant to corrosion, it’s not invincible. Protecting casters from harsh conditions can extend their lifespan significantly. Don't forget that even small changes can yield lasting benefits.

Common Industries That Rely on Stainless Casters for Efficiency

In many industries, stainless casters play a crucial role. They provide mobility and support for various applications. According to a recent industry report, the demand for stainless casters is expected to grow by 5.2% annually. This trend highlights their importance in areas like food processing and pharmaceuticals.

Food processing facilities often rely on stainless casters for hygiene and efficiency. Casters made from stainless steel resist corrosion and facilitate easy cleaning. These features are vital, as a clean environment is essential for food safety. A study found that 75% of food processing facilities prioritize wheels and casters that are easy to maintain.

In the pharmaceutical sector, missteps can have serious consequences. Stainless casters enhance the safety and reliability of equipment. They reduce the risk of contamination. Also, a significant percentage of pharmaceutical companies report using them for improved operational efficiency. Data shows that nearly 60% of these companies experience fewer equipment failures with stainless solutions. Self-reflection on usage can lead to better strategies and practices, improving workflows.

Related Posts

-

Essential Checklist for Choosing the Best Stainless Casters for Your Business Needs

-

Ultimate Guide to Choosing the Right Stainless Casters for Your Needs

-

Understanding the Differences Between Swivel Plate Casters and Fixed Casters

-

Best Stainless Casters for Smooth Mobility Which One to Choose?

-

How to Choose the Best Caster Swivel Wheel for Your Needs?

-

Exploring the Versatile Applications of Best Furniture Castors in Modern Workspace Design